Products 제품리스트 전체보기

PRODUCT NAME

Stainless steel cable glands

Metric

PG

G(PF)

NPT

Thread: Metric, PG, G(PF), and NPT thread

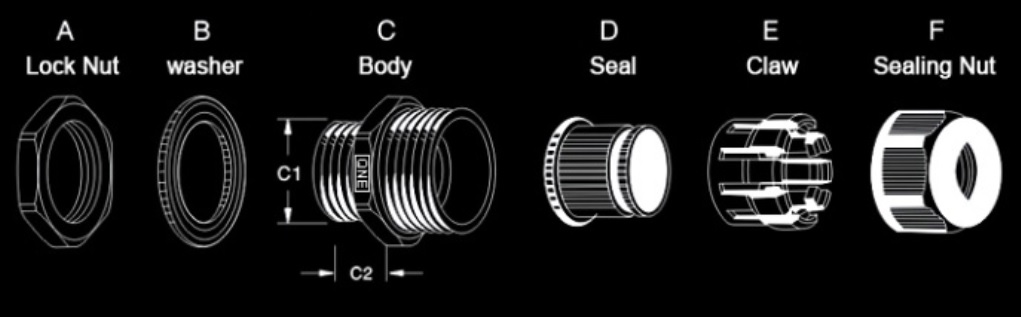

Features: The claws and seals of excellent design, can hold cable firmly and have a wider cable range. Resistant to salt water, weak acid, alcohol, oil, grease and common solvency.

304 stainless steel is the most widely used as a chromium - nickel stainless steel. It has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Stamping, bending and other thermal processing, and no heat treatment hardening (non-magnetic, temperature -196 ℃ ~ 800 ℃), which is widely used in every industry. Corrosion in the atmosphere, industrial atmosphere or if it is heavily contaminated areas, the need for timely clean to avoid corrosion. 304 stainless steel is widely used to produce good overall performance requirements (corrosion resistance and formability) of equipment and parts, whose general temperature limit is less than 650 ℃. 304 stainless steel with excellent corrosion resistance and good resistance to intergranular corrosion。 Obtained in experiments on oxidizing acid:The concentration of ≤65% below the boiling temperature of nitric acid, 304 stainless steel has strong corrosion resistance. And most of the alkali solution and organic acids and inorganic acids also have good corrosion resistance

| Thread | Item. No. | Cable Range |

Thread O. D. |

Thread Length |

Spanner Size |

Std. Pkg |

|---|---|---|---|---|---|---|

| Ф(mm) | C1(mm) | C2(mm) | A&F(mm) | (pcs) | ||

| M6 x 1 | SSCG-M6 -3 | 1.5-3 | 6 | 6 | 9/9 | 20 |

| M8 x 1.25 | SSCG-M8 -3.8 | 2-3.8 | 8 | 6 | 12/12 | 20 |

| M10 x 1.5 | SSCG-M10 -5.5 | 2-6.5 | 10 | 6.5 | 14/14 | 20 |

| M12 x 1.5 | SSCG-M12S-5.5 | 2-6.5 | 12 | 7 | 14/14 | 20 |

| M12 x 1.5 | SSCG-M12-5.5 | 3-5.5 | 12 | 8 | 17/17 | 10 |

| M12 x 1.5 | SSCG-M12-7.8 | 4.5-8 | 12 | 8 | 17/17 | 10 |

| M16 x 1.5 | SSCG-M16S-5.5 | 3-5.5 | 16 | 9 | 18/18 | 10 |

| M16 x 1.5 | SSCG-M16S-7.8 | 4.5-8 | 16 | 9 | 18/18 | 10 |

| M16 x 1.5 | SSCG-M16-7 | 4-7 | 16 | 9 | 22/22 | 10 |

| M16 x 1.5 | SSCG-M16-10 | 6-10 | 16 | 9 | 22/22 | 10 |

| M20 x 1.5 | SSCG-M20S-8.8 | 4-8.8 | 20 | 9.5 | 24/24 | 10 |

| M20 x 1.5 | SSCG-M20S-12.5 | 7-12.5 | 20 | 9.5 | 24/24 | 10 |

| M20 x 1.5 | SSCG-M20-11 | 7-11 | 20 | 9.5 | 26/26 | 10 |

| M20 x 1.5 | SSCG-M20-14 | 9-14 | 20 | 9.5 | 26/26 | 10 |

| M25 x 1.5 | SSCG-M25S-11 | 7-11 | 25 | 12 | 26/26 | 10 |

| M25 x 1.5 | SSCG-M25S-14 | 9-14 | 25 | 12 | 26/26 | 10 |

| M25 x 1.5 | SSCG-M25-16 | 12-16 | 25 | 12 | 32/32 | 10 |

| M25 x 1.5 | SSCG-M25-18 | 14-18 | 25 | 12 | 32/32 | 10 |

| M32 x 1.5 | SSCG-M32-22 | 16-22 | 32 | 12.5 | 40/40 | 10 |

| M32 x 1.5 | SSCG-M32-25 | 18-25 | 32 | 12.5 | 40/40 | 10 |

| M40 x 1.5 | SSCG-M40-26 | 21-26 | 40 | 15 | 50/50 | 10 |

| M40 x 1.5 | SSCG-M40-31 | 24-31 | 40 | 15 | 50/50 | 10 |

| M50 x 1.5 | SSCG-M50-33 | 25-33 | 50 | 15 | 60/60 | 10 |

| M50 x 1.5 | SSCG-M50-41 | 31-41 | 50 | 15 | 60/60 | 10 |

| M63 x 1.5 | SSCG-M63-45 | 35-45 | 63 | 17 | 70/70 | 5 |

| PG7 | SSCG-PG7S-5.5 | 2-6.5 | 12.5 | 7 | 14/14 | 20 |

| PG7 | SSCG-PG7-5.5 | 3-5.5 | 12.5 | 8 | 17/17 | 10 |

| PG7 | SSCG-PG7-7.8 | 4.5-8 | 12.5 | 8 | 17/17 | 10 |

| PG9 | SSCG-PG9-5.5 | 3-5.5 | 15.2 | 8 | 18/18 | 10 |

| PG9 | SSCG-PG9-7.8 | 4.5-8 | 15.2 | 8 | 18/18 | 10 |

| PG11 | SSCG-PG11-7 | 4-7 | 18.6 | 9 | 22/22 | 10 |

| PG11 | SSCG-PG11-10 | 6-10 | 18.6 | 9 | 22/22 | 10 |

| PG13.5 | SSCG-PG13.5-8.8 | 4-8.8 | 20.4 | 9.5 | 24/24 | 10 |

| PG13.5 | SSCG-PG13.5-12.5 | 7-12.5 | 20.4 | 9.5 | 24/24 | 10 |

| PG16 | SSCG-PG16-11 | 7-11 | 22.5 | 9.5 | 26/26 | 10 |

| PG16 | SSCG-PG16-14 | 9-14 | 22.5 | 9.5 | 26/26 | 10 |

| PG21 | SSCG-PG21-16 | 12-16 | 28.3 | 12 | 32/32 | 10 |

| PG21 | SSCG-PG21-18 | 14-18 | 28.3 | 12 | 32/32 | 10 |

| PG29 | SSCG-PG29-22 | 16-22 | 37 | 12.5 | 40/40 | 10 |

| PG29 | SSCG-PG29-25 | 18-25 | 37 | 12.5 | 40/40 | 10 |

| PG36 | SSCG-PG36-26 | 21-26 | 47 | 15 | 50/50 | 10 |

| PG36 | SSCG-PG36-31 | 24-31 | 47 | 15 | 50/50 | 10 |

| PG42 | SSCG-PG42-33 | 25-33 | 54 | 15 | 60/60 | 10 |

| PG42 | SSCG-PG42-41 | 31-41 | 54 | 15 | 60/60 | 10 |

| PG48 | SSCG-PG48-45 | 35-45 | 59.3 | 17 | 70/70 | 5 |